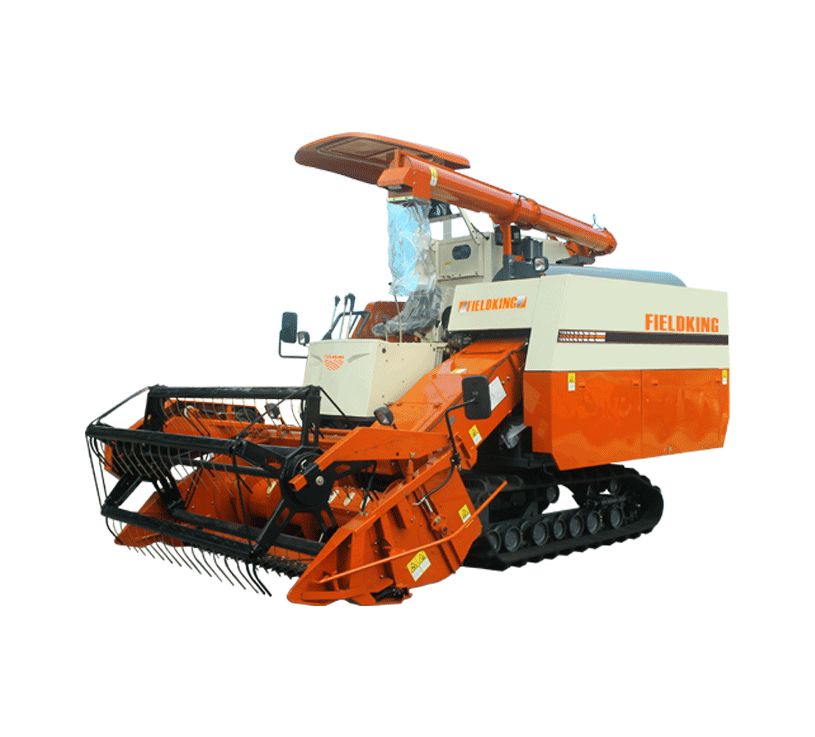

MCH 111

by Hind Multi Crop Harvester

MCH 111

by Hind Multi Crop Harvester

About this item

Multi Crop Harvester

Combine Harvester

HST (Hydrostatic transmission) with 42cc & electromagnetically operated valves for high efficiency and easy steering and operations in the field.

Longer & wider rubber track causes less ground pressure which makes its operation smoother and quicker in swampy, uneven and wet fields.

Vertical threshing rotor and strong concave sieves.

2.2 meter cutter bar helps in harvesting more acres per hour.

Larger feeding bridge with better feeding capacity.

Compact Size body makes it convenient for working in uneven, wet, swampy and small fields

The machine is light-weight which reduces the earth pressure and makes it convenient for the operation in swampy and wet fields

This Multi Crop Combine Harvester is capable of harvesting multiple types of crops - paddy, wheat, corn, barley, pulses & soybean effectively and efficiently

MCH 88 / MCH 100 powerful Engines makes harvesting operations smoother and quicker.

Grain Tank capacity is 1600 liters due to which allows it to reduce time of refueling and unloading of grains which results in more productivity

Axial flow technology thresher ensures less damage of grains and grains are much more cleaner & unbroken during processing in the thresher

Specifications

A combine harvester is a complex machine that consists of intricate components and detailed workmanship. This versatile machine has various parts that perform specific functions, including:

The header is the most important part that cuts the crop and moves them into the machine. The various types of headers include platform header and traditional cutter bar.

There is a threshing segment that shakes the grain and separates it from straws and pods.

This grain then passes through the cleaning system to get rid of any chaff, debris or residue.

The cleaned grains then reach the crop tank while the unwanted chaff is headed through a different conveyor.

The harvested crop is stored until it is ready to be unloaded, while the crop residue is chopped into a smaller size to ease its exit out of the machine.